Hydraulic Chucks (for Rotating Applications) from the Standard Tool Holder Product Line

Features and Benefits

- Runout accuracy of less than .00012"

- Low torque is required to activate the clamping mechanism

- Prolongs cutting tool life and improves surface finish due to vibration damping

- Internal preset screw allows for quick and easy presetting

- Consistent and secure clamping force

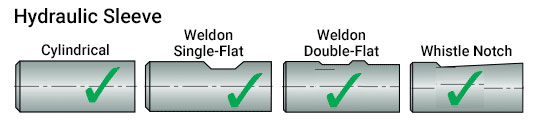

- Suitable for use with both cylindrical and flatted shank tools

- Safe and convenient tool change on the machine

Product Ranges & Details

Main Applications:

Fine & Accurate Machining

Reaming

Drilling

Finish Milling

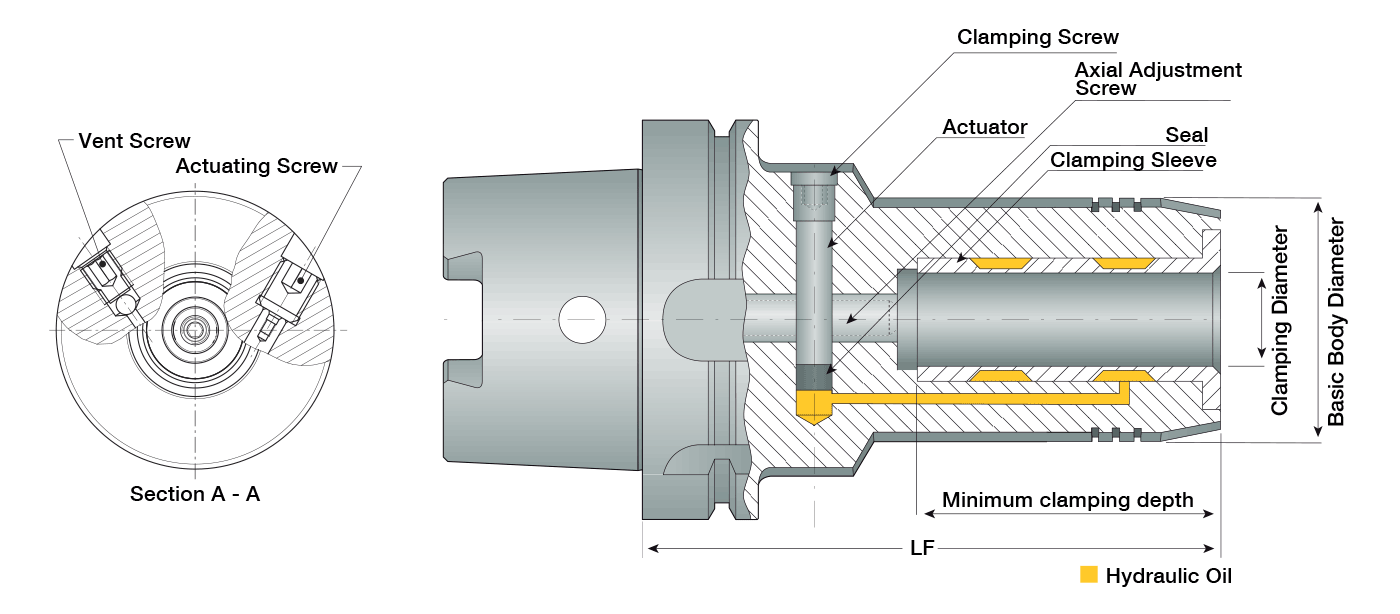

Hydraulic Chuck Operating Instructions

To ensure optimal performance and proper function of the hydraulic chuck, the use and care guidelines should always be followed. Tools with cylindrical shanks and shanks with one Weldon flat should have h6 tolerance. Tools with whistle-notch shanks or with two Weldon flats should be used in reduction sleeves to avoid damaging the chucking bore.

- The tool shank most be burr-free and free of dirt. Insert the tool shank up to the stopper, making sure that the minimum holding length is maintained. lf the minimum holding depth is not met, there will be a loss of accuracy, the maximum admissible torque will be reduced, and the tool holder might get damaged.

- The clamping screw must be turned in manually with an Allen key to the limit stop. DO NOT APPLY EXCESSIVE FORCE. Tightening torque: Max.10 N•m. Never actuate the actuation screw with a power screwdriver!

- Do not attempt to clamp the chuck without a shank inside, as this will damage the expansion clamping sleeve.

- To release the tool, turn the clamping screw in a counter-clockwise direction until tool can be removed. The clamping screw is not secured against dropping out!

- The vent screw of the hydraulic system is protected with a resin. Don't remove it!

- The use of flatted shank tooling can influence the balancing grade and run-out accuracy of the whole system

- Maximum speed must be reduced if longer, overhanging, or heavy tools and extensions are used. It is the operator’s responsibility to determine the reduction in speed required specific to the application.

- The balancing quality can also change with the use of long, overhanging, or heavy tools and extensions. It is the operator’s responsibility to adjust accordingly specific to the application

- Optimal operating temperature range is 68-122°F

- Max Coolant Pressure 1160 PSI

Care, Storage, and Maintenance

- The clamping bore and groove should be thoroughly cleaned with a solvent cleaning agent after every tool change.

- The entire surface of the hydraulic holder should be lightly oiled prior to storage to protect from corrosion.

- The hydraulic holder should always be stored in an unclamped position

- In instances of a high number of clamping cycles, high operating temperatures, and abrasive dirt or swarf, it may be necessary to adjust cleaning and lubrication of the clamping screw.

- For optimal lubrication, use of copper paste MOLYKOTE CU 7439 is recommended.

Runout Accuracy

Minimum Torque Transmission

| Shank Diameter in / mm |

Torque ft lb / N•m |

Min. Holding Length inch / mm |

| 1/4" / 6 mm | 11 ft lb / 15 N•m | 1.063" / 27 mm |

| 8 mm | 18.5 ft lb / 25 N•m | 1.063" / 27 mm |

| 3/8" / 10 mm | 37 ft lb / 50 N•m | 1.26" / 32 mm |

| 1/2" / 12 mm | 81 ft lb / 110 N•m | 1.46" / 37 mm |

| 14 mm | 118 ft lb / 160 N•m | 1.46" / 37 mm |

| 5/8" / 16 mm | 177 ft lb / 240 N•m | 1.65" / 42 mm |

| 18 mm | 258 ft lb / 350 N•m | 1.65" / 42 mm |

| 3/4" / 20 mm | 295 ft lb / 450 N•m | 1.65" / 42 mm |

| 1" / 25 mm | 369 ft lb / 500 N•m | 1.89" / 48 mm |

| 1-1/4" / 32 mm | 369 ft lb / 500 N•m | 2.047" / 52 mm |

Quick Clamping Test for Hydraulic Chucks

To perform a quick test for accurate clamping force of a Hydraulic Milling Chuck using a Hydraulic Test Bar, insert the Hydro Test Bar into the Hydraulic Chuck and rotate the clamping screw until touching the Hydro Test Bar just to the point to where the Hydro Test Bar is seized and cannot be removed. Once the bar is seized, count the number of rotations until the clamping screw is fully inserted and compare to values in the table below. If the number of rotations does not match the value for the bore diameter being tested, the Hydraulic Chuck requires further inspection for repair or replacement.

| Chuck Diameter - mm (inch) | Number of rotations |

| 6mm (1/4”) | 2 |

| 8mm | 2-1/2 |

| 10mm (3/8”) | 2-1/2 |

| 12 mm (1/2”) | 3 |

| 14 mm | 3-1/2 |

| 16mm (5/8”) | 3-1/2 |

| 18mm | 3-1/2 |

| 20mm (3/4”) | 4-1/2 |

| 25mm (1”) | 5-1/2 |

| 32mm (1 1/4”) | 6 |