Untitled Document

EDP: 5523121 Part: CNGG120402ML TT5080 Series: CNGG ML Chipbreaker

EDP: 5523121 Part: CNGG120402ML TT5080 Series: CNGG ML Chipbreaker

View STEP

Available : 1200

International: 5737

Product Series Features:

- Negative 80° rhombic ground inserts

- For medium applications

- Very sharp

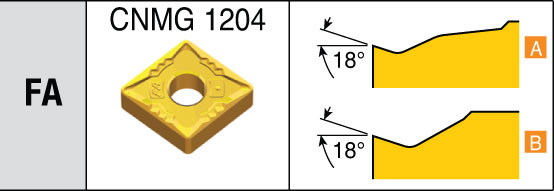

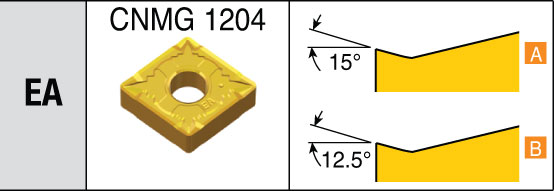

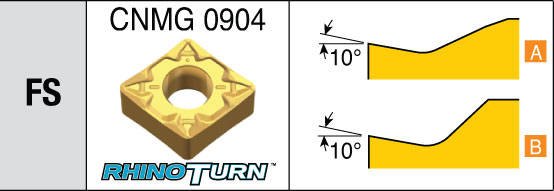

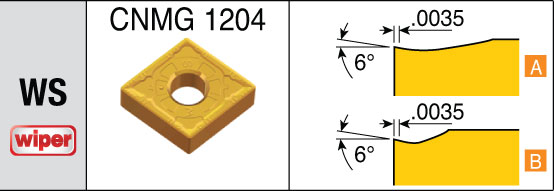

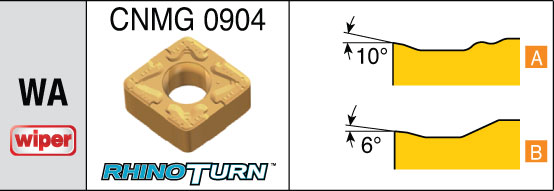

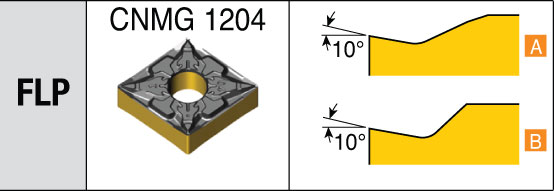

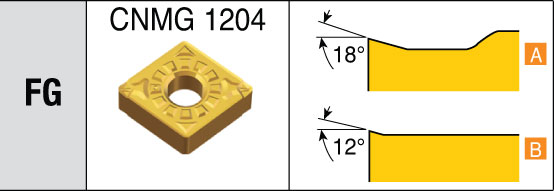

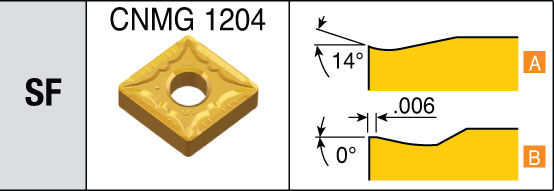

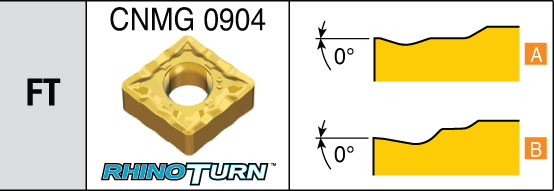

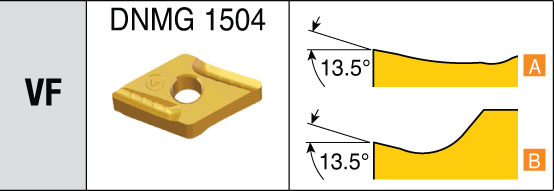

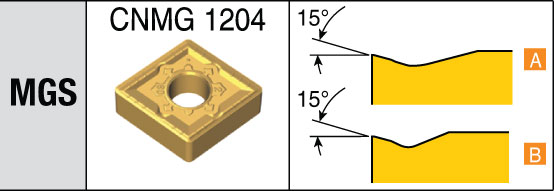

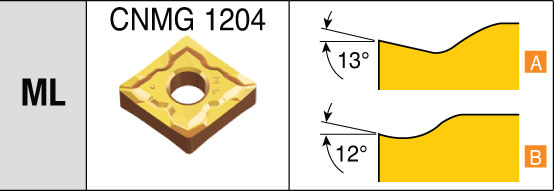

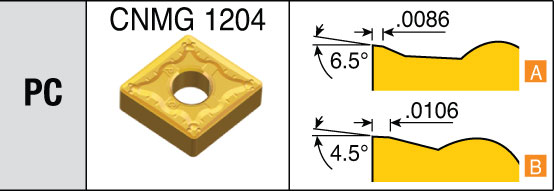

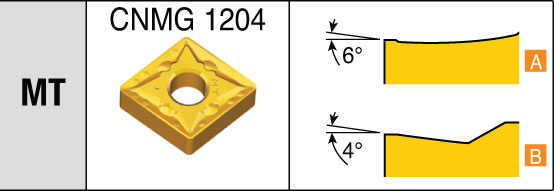

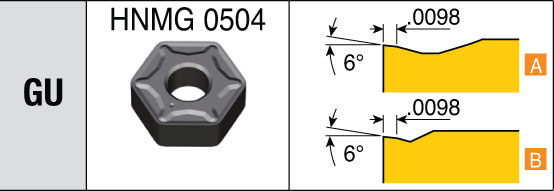

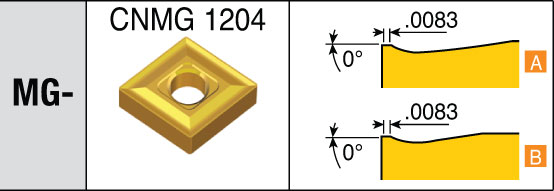

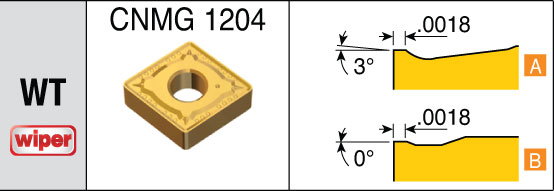

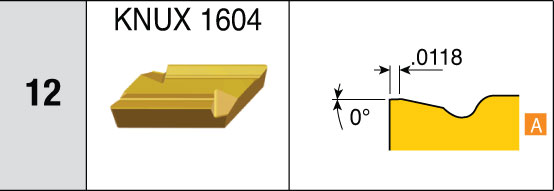

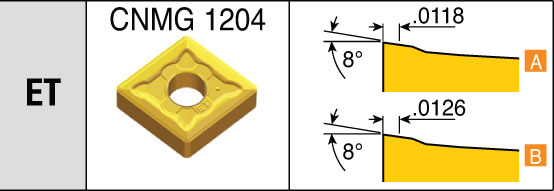

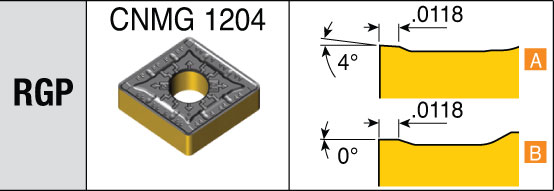

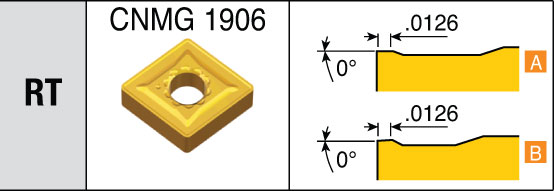

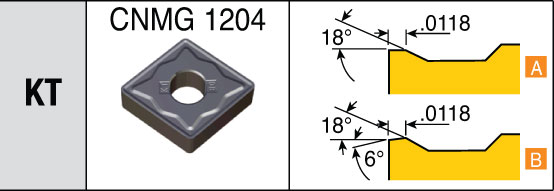

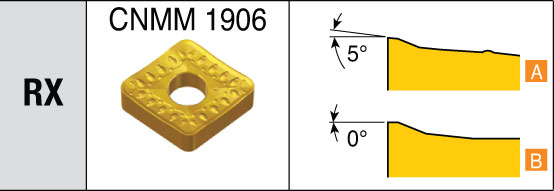

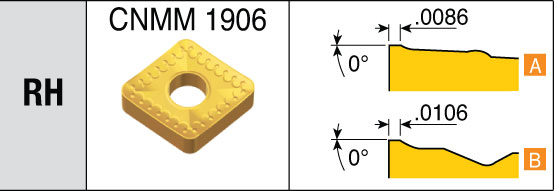

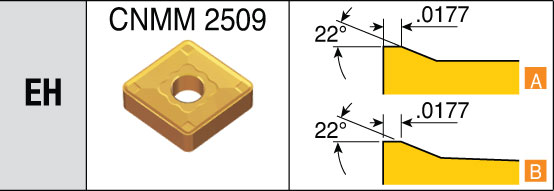

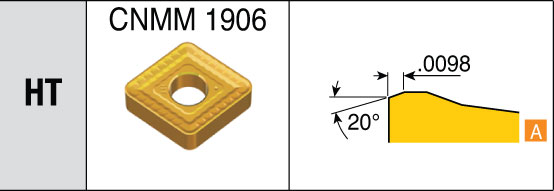

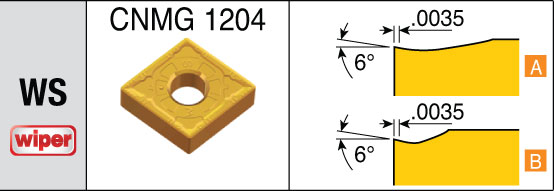

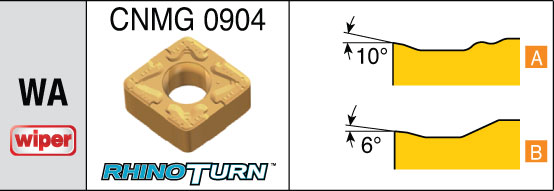

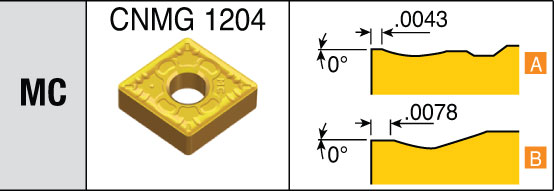

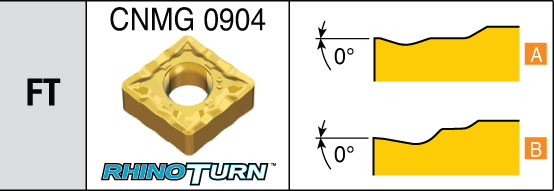

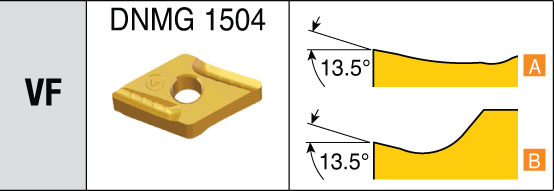

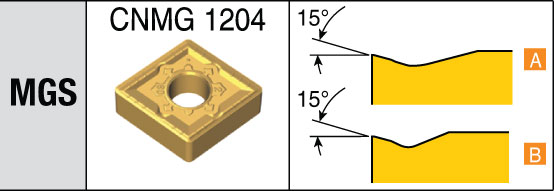

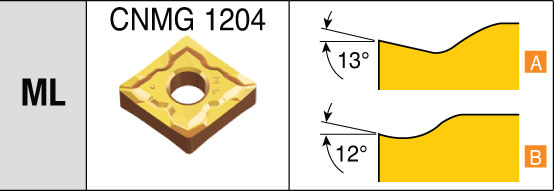

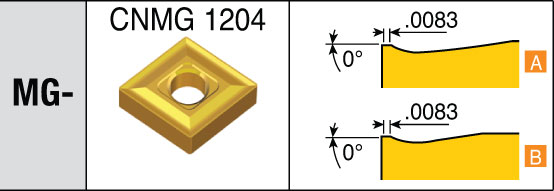

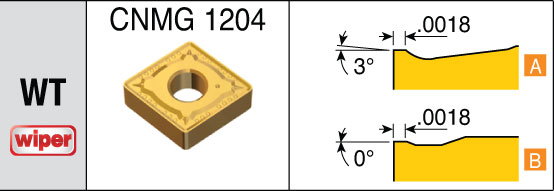

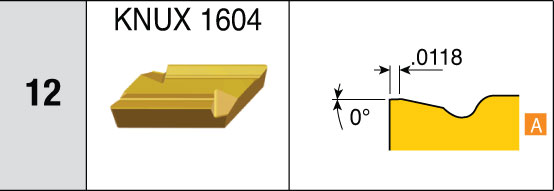

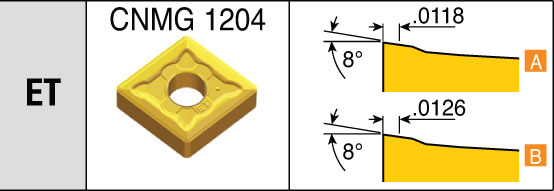

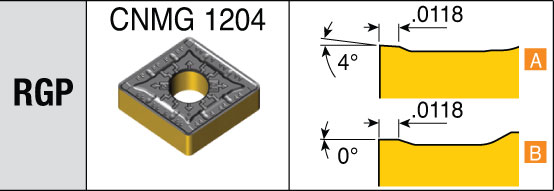

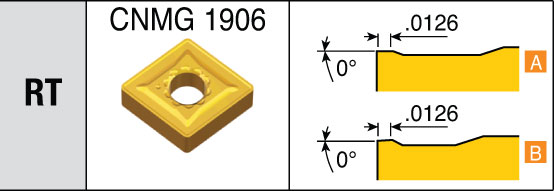

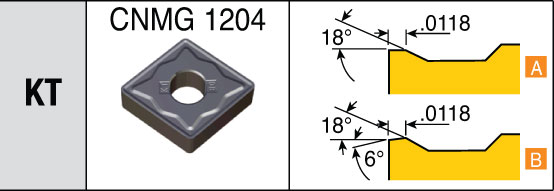

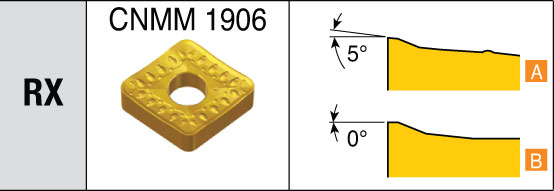

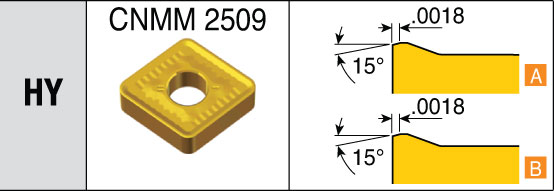

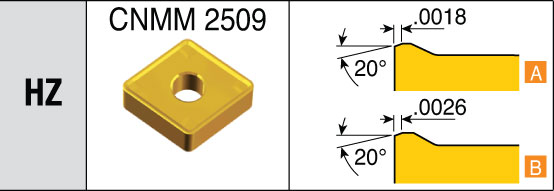

Negative Chipbreaker Insert Cross-Sections

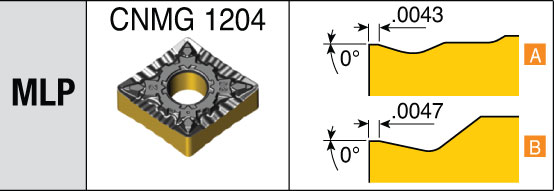

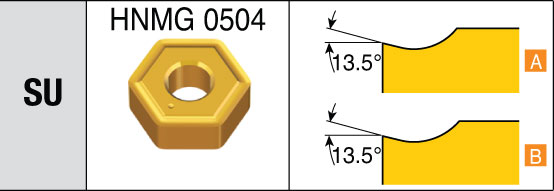

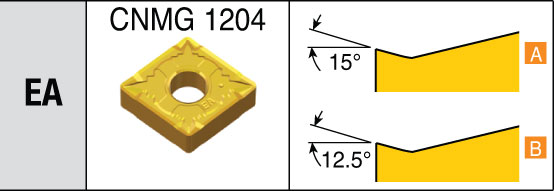

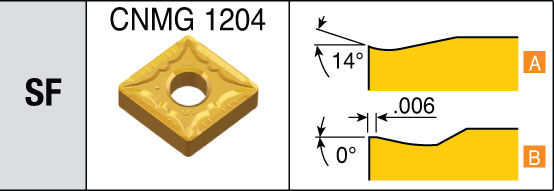

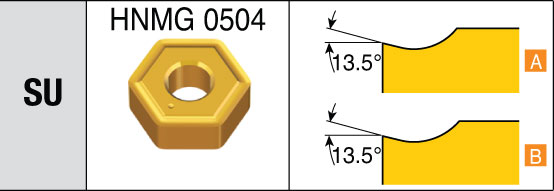

Negative Super Finishing Inserts

- For super finish applications

- Steel, stainless steel and heat resistant alloy machining

- Excellent chip control

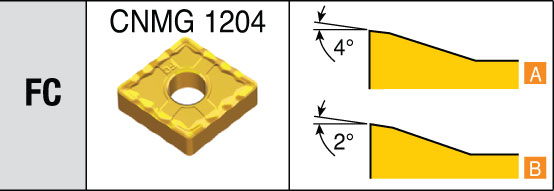

- For finishing applications

- Exotic materials

- Excellent chip control at low feeds and depths of cut

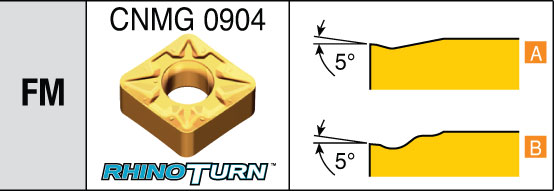

- Super finishing chip breaker for steel machining

- Excellent chip control and chip evacuation

- Minimal vibration due to less machining load

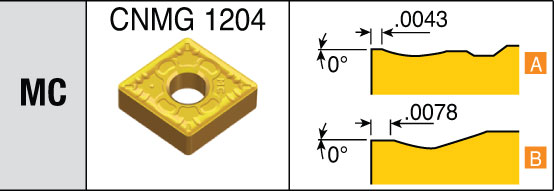

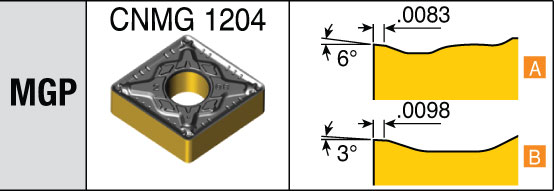

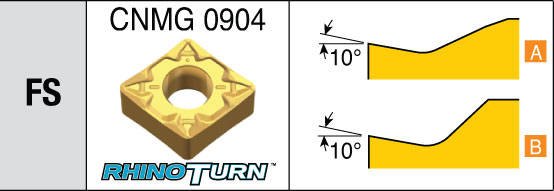

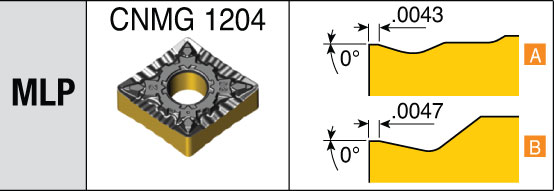

- For super finish applications

- Steel, cast iron and stainless steel machining

- Excellent chip control and low cutting forces

- For super finish applications

- Steel, cast iron and stainless steel machining

- Excellent surface roughness after machining

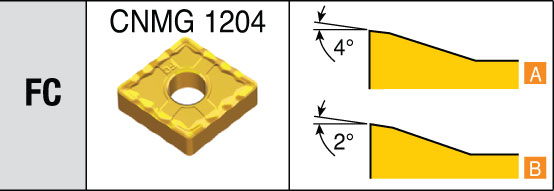

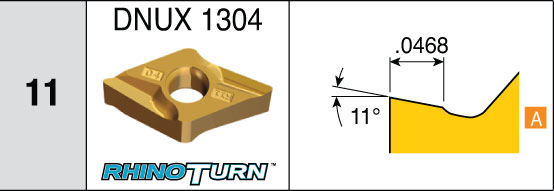

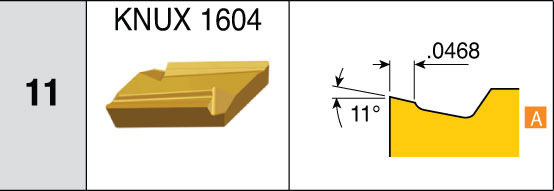

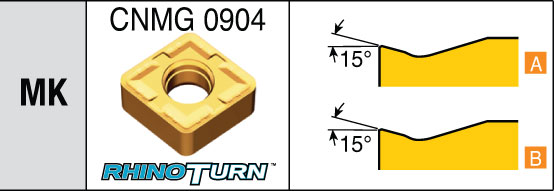

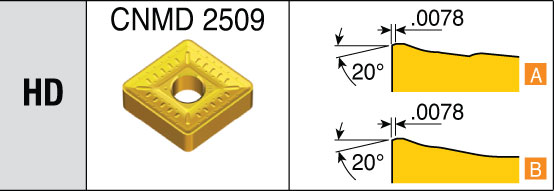

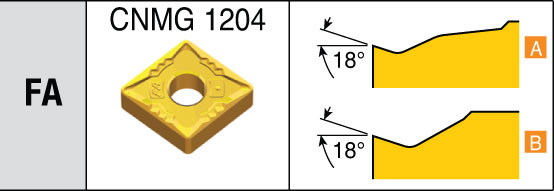

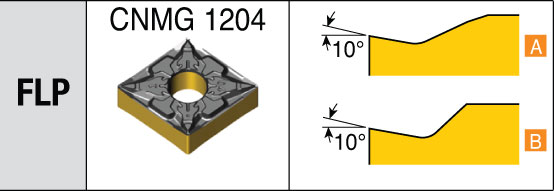

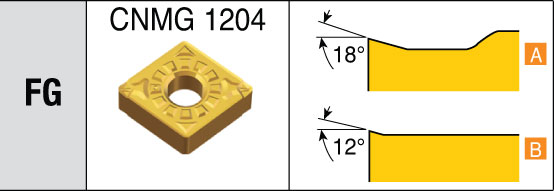

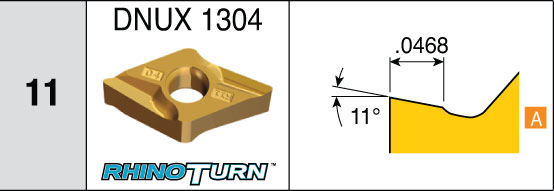

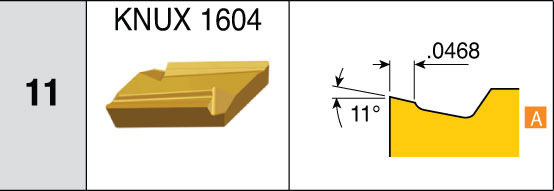

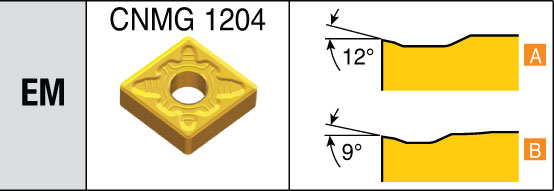

Negative Finishing Inserts

- For finishing applications for steel machining

- Wide supporting area

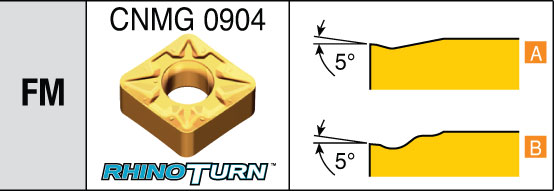

- For finish and semi finish applications

- Steel, stainless steel and cast iron machining

- Low cutting forces

- For finishing applications

- Stainless steel and heat resistant alloy machining

- Low cutting forces

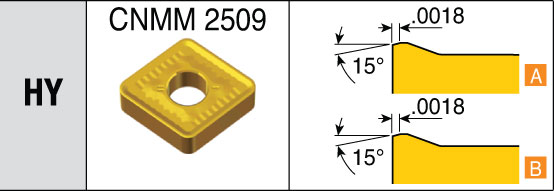

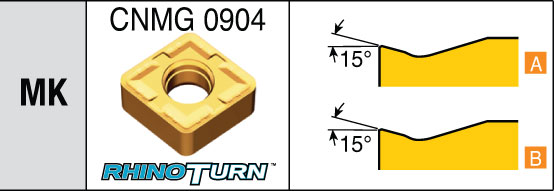

- For finishing applications on mild steels

- Narrow chip breaker design for optimal chip control

- Ideal for finishing applications

- Low carbon steel & low carbon alloy steel

- Effective chip breaking in both turning and facing operations

- For steel machining

- Improved chip breaking due to 3-dimension chipbreaker

- Solution for a wide range from semi-finishing to semi-medium machining

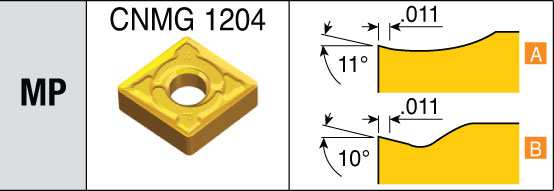

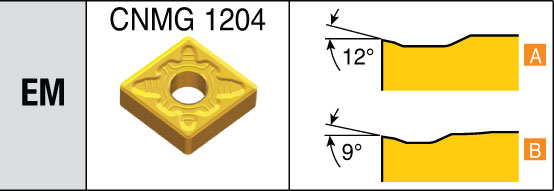

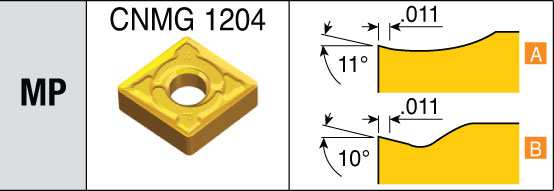

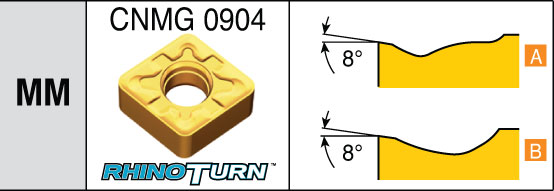

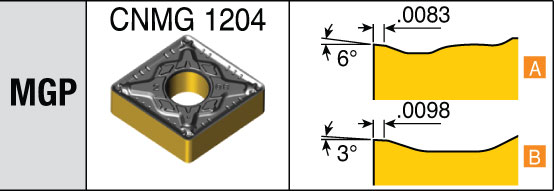

Negative Medium Inserts

- For semi-finishing and medium applications on steels

- Wave cutting edge

- For medium applications

- Steel and cast iron machining

- Strong rake geometry

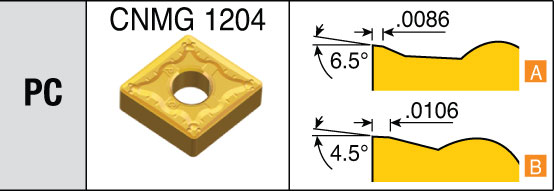

- Excellent chip control on medium turning applications

- For steel machining

- Strong, serrated cutting edge for excellent chip evacuation

- Semi-finishing and medium machining

- Excellent chip breaking for automotive components

- For slender workpiece applications

- Vibration free

- Steel and stainless steel machining

- High positive rake geometry to minimize cutting forces

- Low cutting resistance and heat generation high-temperature alloy machining

- High rake angle for smooth chip formation

- For medium light applications

- Stainless steel, steel and aluminum

- Very high positive rake geometry to minimize built-up-edge and cutting forces

- For exotic materials

- Stainless steels, super alloys, low carbon steels, low carbon alloy steel machining

- Sharp geometry to minimize built-up edge

- For medium applications less than 5mm depth of cut

- Steel and stainless steel machining

- Positive rake geometry to decrease cutting forces

- Suitable for turning slender bar, thin-wall components

- For medium light to medium applications

- Steel and stainless steel machining

- Positive rake geometry to minimize cutting forces

- Excellent chip control

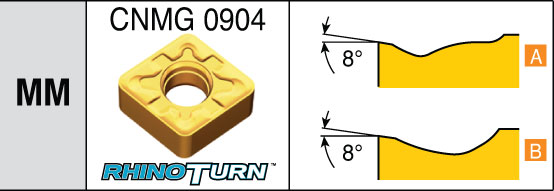

- For medium machining applications

- Steel and stainless steel

- High positive rake geometry to optimize machining and provide stable machining conditions

- For medium applications

- Stainless steel machining

- Sharp land design for low cutting force

- For medium applications

- Stainless steel and heat resistant material machining

- Sharp cutting edge to reduce built-up-edge

- For general machining on stainless steel and steel

- Positive rake angle provides excellent chip evacuation

- Wide range for medium application on steels

- Wide groove and several dimples

- For medium to semi-finishing applications

- Steel & Automotive component

- Positive geometry

- Excellent chip control on medium applications

- For medium rough applications

- Steel, cast iron and stainless steel

- Tough rake angle for general use

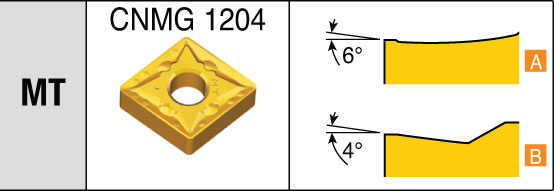

- For medium applications

- For general turning of steels and cast irons

- Strong rake geometry

- For medium rough applications

- Steel and cast iron machining

- Strong rake geometry

- Suitable for manual lathes

- For medium to rough machining applications

- Steel, cast iron and stainless steel machining

- Stable cutting and low cutting forces at high feed rates

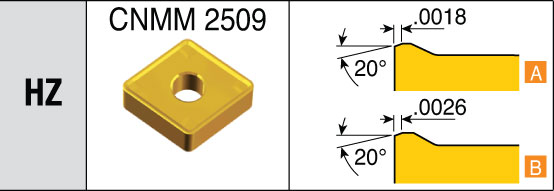

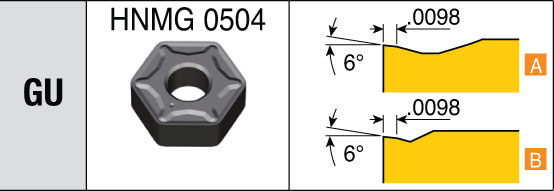

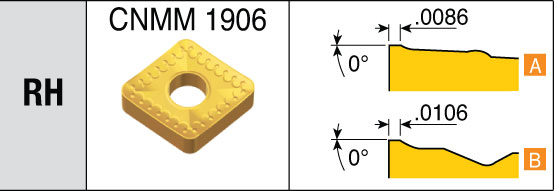

Negative Roughing Inserts

- For medium to medium rough applications

- Steel and stainless steel

- Strong rake geomerty

- Wide chip control range

- For roughing applications on exotic materials

- Low cutting force

- Wide chip control range when roughing

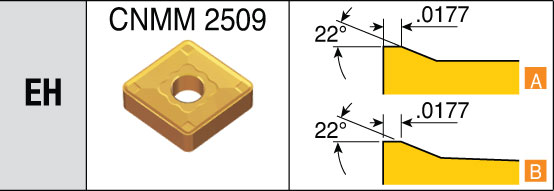

- For roughing applications on steels

- Reliable cutting edge with low cutting force

- For roughing applications

- Steel and cast iron machining

- Very strong rake geometry

- For roughing applications on cast iron

- Stable broad supporting area

- Reliable, uniform performance

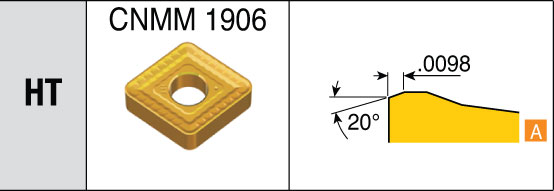

- For semi heavy roughing applications

- Steel, stainless steel and cast iron machining

- Strong cutting edge with flat land

- Low cutting force

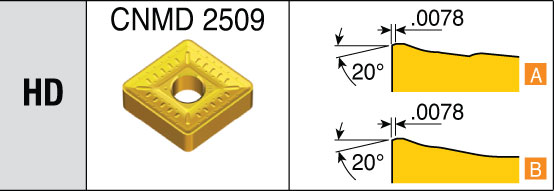

- For roughing applications

- Steel, stainless steel and cast iron machining

- Very strong rake geometry

- Heavy turning for stainless and mild steel

- Low cutting force in stainless steel machining

- Reliable & uniform performance

- Excellent chip control due to the specially designed chip breaker geometry

- For heavy roughing applications

- Low cutting force for low horse power machines

- Excellent chip control due to changeable land and a flexible chip breaker

- For heavy roughing applications

- For all kinds of shafts, connecting-rods and ship building components

- Flexible chip breaker offers excellent chip evacuation

- For heavy roughing applications

- For large depth of cut and high feed

- Strong cutting edge credit to a wide land and large land angle

- For heavy roughing applications

- For large depth of cut and high feed

- Extremely strong cutting edge credit to a wide land and large land angle

- Suitable for high cutting conditions