Series: TDT-E RU

Series: TDT-E RU

Representative image shown ⓘ

The image above is intended to represent the product series for illustrative purposes only. The actual product may vary.

Product Series Features:

- Full Radius

- Pressed Double-Ended Insert

- For Turning, Grooving, & Profiling

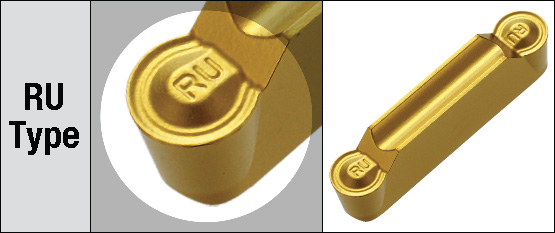

- RU-Type Chipbreaker

Part Number |

SSC Insert Seat Size |

CW Cutting Width |

RE Corner Radius |

CDX Cutting Depth Max. |

WB Body Width |

INSL Insert Length |

S1 Thickness |

DAXIN Axial Groove I.D. Min. |

DMIN Min. Bore Dia. |

FEEDGN Grooving Feed Min. |

FEEDGX Grooving Feed Max. |

FEEDN Turning Feed Min. |

FEEDX Turning Feed Max. |

APMN Turning Depth of Cut Min. |

APMX Turning Depth of Cut Max. |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TDT4E-2.0-RU | 4 | 0.157 | 0.079 | 0.709 | 0.118 | 20.00 mm | 0.185 | 1.417 | 1.496 | 0.0040 | 0.0080 | 0.007 | 0.014 | 0.001 | 0.079 |

Part Number |

SSC Insert Seat Size |

CW Cutting Width |

RE Corner Radius |

CDX Cutting Depth Max. |

WB Body Width |

INSL Insert Length |

S1 Thickness |

DAXIN Axial Groove I.D. Min. |

DMIN Min. Bore Dia. |

FEEDGN Grooving Feed Min. |

FEEDGX Grooving Feed Max. |

FEEDN Turning Feed Min. |

FEEDX Turning Feed Max. |

APMN Turning Depth of Cut Min. |

APMX Turning Depth of Cut Max. |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TDT2E-1.0-RU | 2 | 0.079 | 0.039 | 0.748 | 0.067 | 20.00 mm | 0.185 | 11.575 | 1.614 | 0.0020 | 0.0060 | 0.004 | 0.010 | 0.001 | 0.039 | |

| TDT3E-1.5-RU | 3 | 0.118 | 0.059 | 0.728 | 0.087 | 20.00 mm | 0.185 | 1.614 | 1.496 | 0.0030 | 0.0070 | 0.006 | 0.011 | 0.001 | 0.059 | |

| TDT4E-2.0-RU | 4 | 0.157 | 0.079 | 0.709 | 0.118 | 20.00 mm | 0.185 | 1.417 | 1.496 | 0.0040 | 0.0080 | 0.007 | 0.014 | 0.001 | 0.079 | |

| TDT5E-2.5-RU | 5 | 0.197 | 0.098 | 0.886 | 0.157 | 25.00 mm | 0.205 | 2.126 | 1.693 | 0.0050 | 0.0090 | 0.008 | 0.016 | 0.001 | 0.098 | |

| TDT6E-3.0-RU | 6 | 0.236 | 0.118 | 0.866 | 0.197 | 25.00 mm | 0.205 | 2.126 | 1.811 | 0.0060 | 0.0100 | 0.010 | 0.021 | 0.001 | 0.118 | |

| TDT8E-4.0-RU | 8 | 0.315 | 0.157 | 1.023 | 0.236 | 30.00 mm | 0.252 | 2.402 | 2.205 | 0.0070 | 0.0130 | 0.011 | 0.026 | 0.001 | 0.157 |

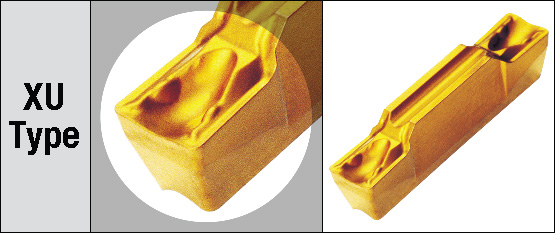

Groove-Turn Chip Breakers

- 1st choice for general use in groove-turn

- Multi functional chip breaker for external, internal, and face machining

- Low cutting force and good chip control

- Medium-to-high feed grooving, low-to-medium feed turning

- Steel, stainless steel and heat resistant alloy

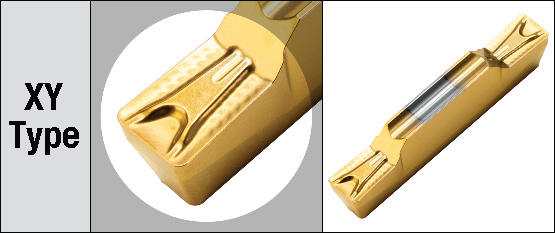

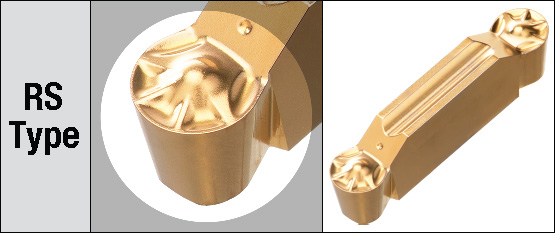

- For external and internal grooving as well as turning applications

- Good chip control when external face grooving and turning

- Flat bottom surface machining

- Low-to-medium feed grooving, medium-to-high feed turning

- Ideal for steel, stainless steel, cast iron and super alloys machining

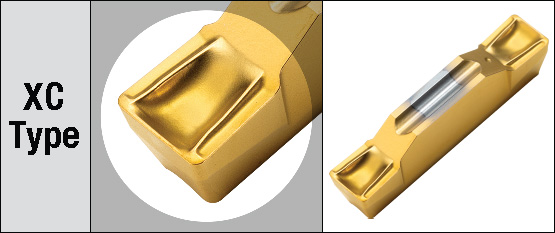

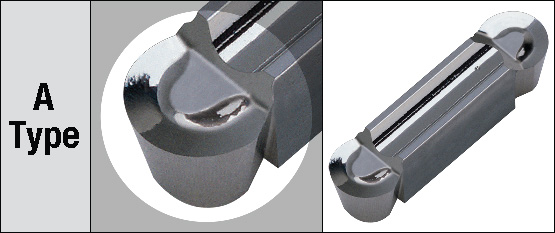

- Stable cutting edge and flat bottom surface machining in grooving and parting

- Covers C-type chip breaker applications including a built-in chip breaker for turning applications

- Medium-to-high feed range

- Steel, cast iron, stainless steel and heat resistant alloys

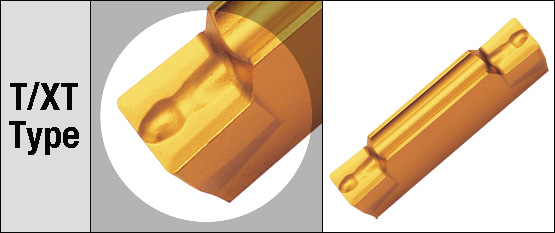

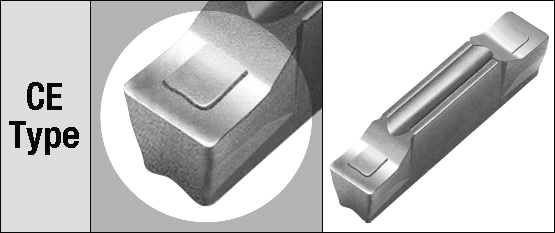

- 1st choice for side turning of cast iron

- Turning and grooving with various geometry

- Steel and cast iron

- High feed rate

- 1st choice for profiling in steel and cast iron

- Tough cutting edge

- Good chip control even in low depth

- Good surface finish

- High feed rate and low depth of cut

- 1st choice for medium to finishing machining of heat-resistant super alloys

- For external and internal profiling, turning and grooving applications

- Low cutting force and good surface finish due to the sharp edge

- Precision machining and excellent repeatability

- 1st choice for profiling in non-ferrous materials

- Very sharp cutting edge

- Ceramic insert

- Recommended for aged cast iron material

- Not recommended for grooving in steel