Series: SCMT MT Chipbreaker

Series: SCMT MT Chipbreaker

Representative image shown ⓘ

The image above is intended to represent the product series for illustrative purposes only. The actual product may vary.

Product Series Features:

- Positive 7° clearance square inserts

- For medium machining

ANSI Number |

ISO Number |

NOI Number of Indexes |

IC Inscribed Circle Dia. |

RE Corner Radius |

L Cutting Edge Length |

S Thickness |

D1 Fixing Hole Dia. |

fn Cutting Feed Min. |

fn Cutting Feed Max. |

ap Cutting Depth Min. |

ap Cutting Depth Max. |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SCMT32.51MT | SCMT09T304MT | 4 | 0.375 | 0.016 | 0.375 | 0.156 | 0.173 | 0.004 | 0.010 | 0.028 | 0.138 | |

| SCMT32.52MT | SCMT09T308MT | 4 | 0.375 | 0.031 | 0.375 | 0.156 | 0.173 | 0.005 | 0.012 | 0.039 | 0.138 | |

| SCMT431MT | SCMT120404MT | 4 | 0.500 | 0.016 | 0.500 | 0.187 | 0.217 | 0.004 | 0.010 | 0.039 | 0.197 | |

| SCMT432MT | SCMT120408MT | 4 | 0.500 | 0.031 | 0.500 | 0.187 | 0.217 | 0.005 | 0.012 | 0.039 | 0.197 | |

| SCMT433MT | SCMT120412MT | 4 | 0.500 | 0.047 | 0.500 | 0.187 | 0.217 | 0.006 | 0.014 | 0.039 | 0.197 |

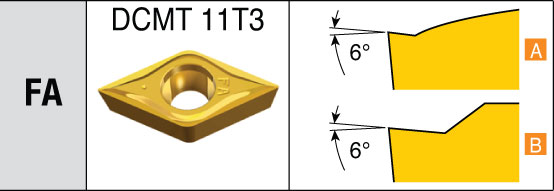

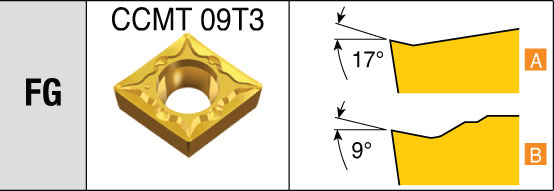

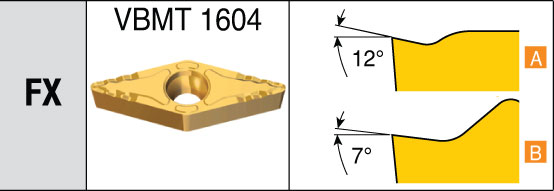

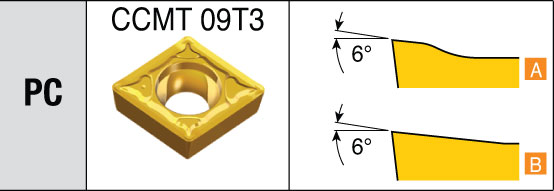

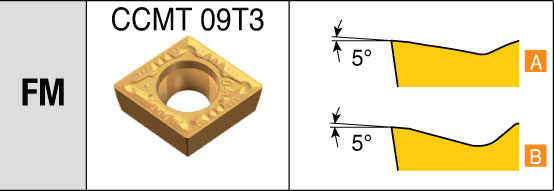

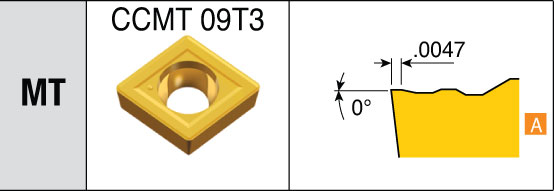

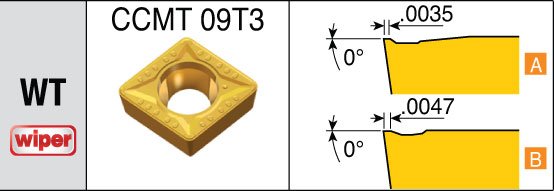

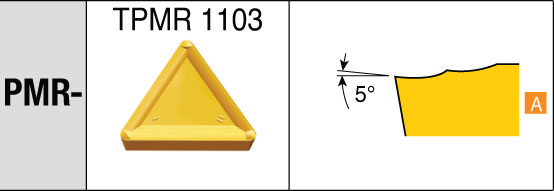

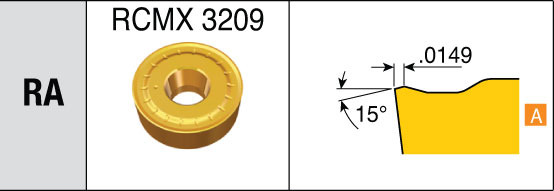

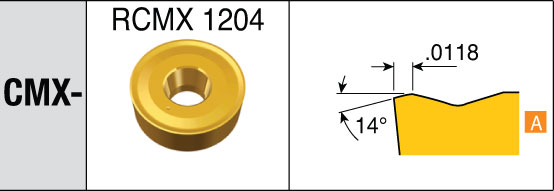

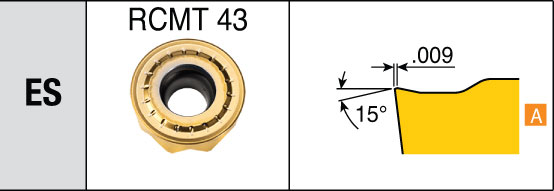

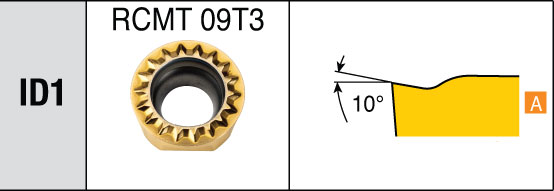

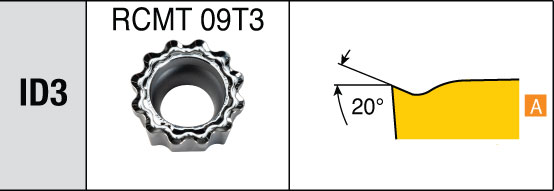

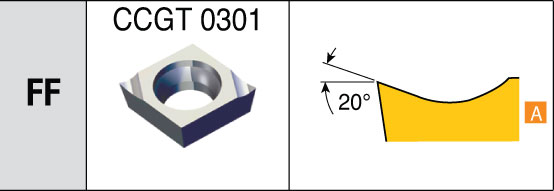

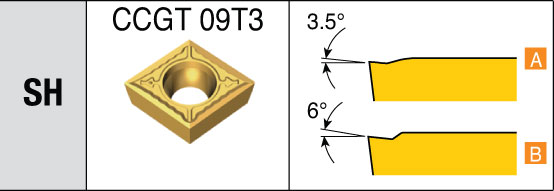

Positive Chipbreaker Insert Cross-Sections

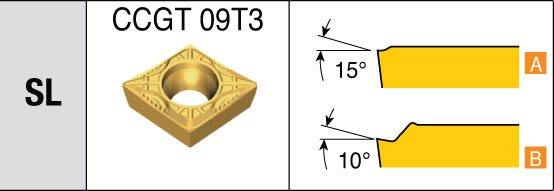

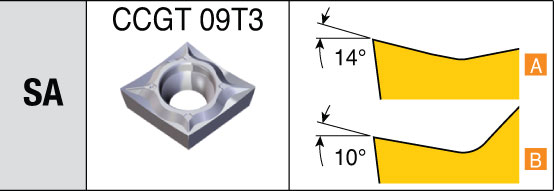

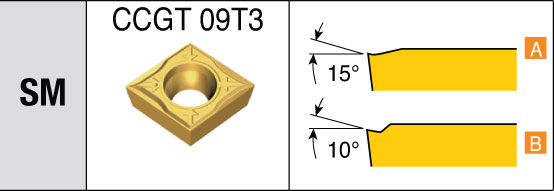

Positive Inserts - Pressed

- For super finish applications

- Very tight chipbreaker

- Excellent chip control

- For finish to medium light applications

- Steel and stainless steel machining

- Low cutting forces

- Excellent chip control

- For finishing applications on mild steels

- Narrow chip breaker design for optimal chip control

- For medium applications

- Suitable for a wide variety of meterials

- Low cutting force

- Medium and semi-finishing machining for steel and stainless steel

- Precision machining

- Low cutting force chip breaker geometry

- For medium to medium rough applications

- Steel, stainless steel and cast iron machining

- Negative rake geometry for general use

- For medium to rough machining applications

- Steel, cast iron and stainless steel machining

- Stable cutting and low cutting forces at high feed rates

- For medium to medium rough applications

- Steel, stainless steel and cast iron

- Positive rake geometry

- For heavy and interrupted machining applications

- Steel, stainless steel and cast iron machining

- Optimized chip groove geometry

- For high feed roughing applications

- Steel, stainless steel and cast iron machining

- Strong rake geometry

- For heavy and interrupted machining application

- Super alloy, steel, and stainless steel machining

- Optimized chip groove geometry

- For general machining application

- Super alloy and stainless steel machiningSharp geometry

- For general machining application

- Non-ferrous machining

- High positive rake geometry

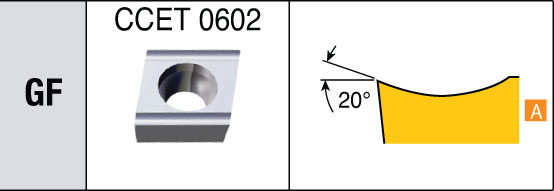

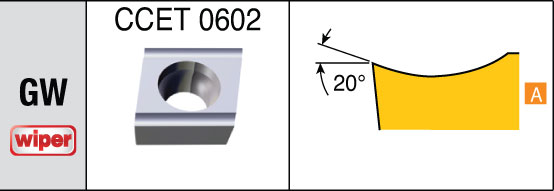

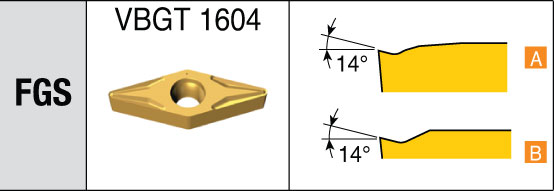

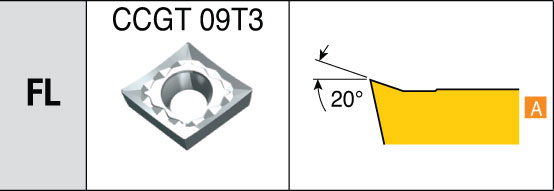

Positive Inserts - Ground

- For finish to medium applications

- For small component machining

- Excellent surface finish

- For super finish applications

- Steel, stainless steel and alloy steel machining

- For super finish applications

- Wiper geometry for good surface finish

- Steel, stainless steel and alloy steel machining

- Lower cutting resistance and heat generation in heat resistant super alloys machining

- High rake angle for smooth chip formation

- High performance in low depth of cut and low feed machining

- Excellent chip segmentation due to wave geometry edge and special inclined design

- For finish to medium applications

- Steel & aluminum machining

- Low cutting force

- 1st recommended chip breaker for Swiss type automatic lathe

- Stable cutting edge and low cutting resistance

- Suitable for deep depth of cut machining

- Excellent chip control in a wide machining range

- For finish to medium applications

- Aluminum machining

- Very high positive rake geometry to minimize built-up-edge